Just How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a considerable development in quality assurance approaches. By providing real-time, specific measurements of Fibre sizes, this technology attends to the vital requirement for consistency in production standards. With its ability to promptly identify inconsistencies and punctual corrective measures, the analyser not only improves product dependability however additionally adds to total functional efficiency. As industries significantly focus on top quality and conformity, comprehending the full influence of such technologies becomes crucial. What ramifications could this have for the future of Fibre production?

Importance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is vital in the area of optical Fibre modern technology, as it directly affects the performance and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, attenuation, and total transmission efficiency. Accuracy in determining Fibre Diameter makes certain that the optical homes are preserved within specified tolerances, which is vital for ideal signal integrity.

Variants in Fibre Diameter can lead to raised losses because of spreading and modal diffusion, affecting the quality of data transmission. In high-speed interaction systems, such inconsistencies can cause significant degradation of signal top quality, resulting in data errors and minimized efficiency. Constant Fibre Diameter is important for compatibility with ports and splicing innovations, which are indispensable components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily rely upon exact Diameter dimensions to ensure compliance with industry criteria. By carrying out robust dimension strategies, makers can improve product integrity, reduce waste, and improve overall system efficiency. Hence, the importance of Fibre Diameter measurement can not be overemphasized, as it functions as a foundation in the innovation of optical Fibre technology and its applications in modern-day communication networks.

Exactly How the Analyser Functions

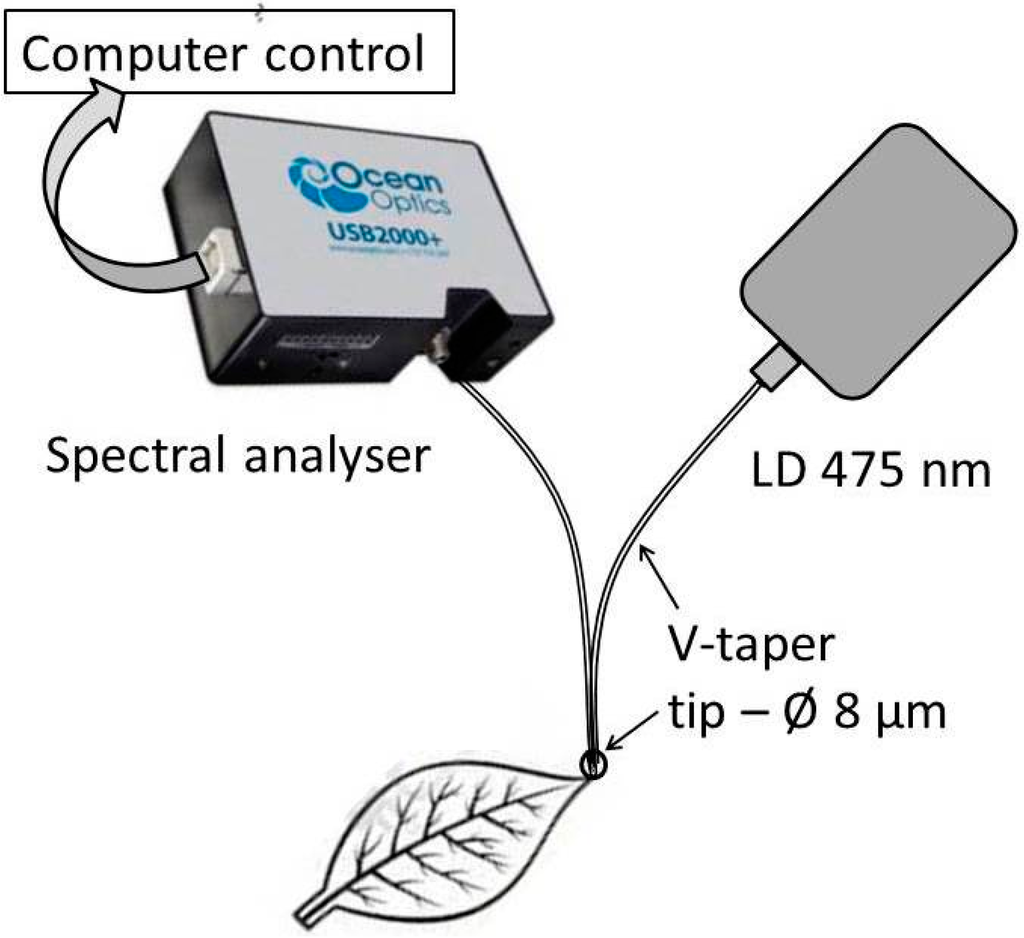

The reliable dimension of Fibre Diameter depends on sophisticated logical strategies that ensure precision and integrity in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser innovation and advanced photo processing algorithms to accurately analyze the Diameter of fibers as they are produced

Originally, a laser beam of light is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this shadow using high-resolution cams placed strategically along the assembly line. The caught photos are then processed in real-time to determine the Fibre's Diameter with outstanding accuracy.

The system utilizes innovative formulas that represent numerous factors, consisting of variants in light intensity and environmental problems, to boost measurement integrity. It can spot minute modifications in Diameter, such as changes that may take place during the manufacturing procedure.

Additionally, the analyser can managing multiple fibers simultaneously, increasing throughput without jeopardizing accuracy. By providing instantaneous comments on the Diameter, the Optical Fibre Diameter Analyser plays a vital role in keeping strict quality assurance standards, making sure that the end product meets market requirements and customer requirements.

Advantages of Real-Time Monitoring

While traditional techniques of checking Fibre Diameter frequently include lengthy post-production checks, real-time surveillance dramatically boosts the performance and top quality of optical Fibre production. optical fibre diameter analyser. This proactive method permits suppliers to identify discrepancies in Fibre Diameter as they occur, instead than waiting up until production is complete to examine top quality

By continuously measuring the Diameter throughout manufacturing, manufacturers can guarantee that the fibres fulfill stringent specifications, causing lowered variability and boosted uniformity. Real-time surveillance additionally enables immediate corrective activities to be taken, lessening waste and avoiding defective fibres from going into the supply chain.

Furthermore, this modern technology helps with boosted data collection and analysis, supplying understandings into production patterns and possible areas for improvement. Such data-driven decision-making equips makers to maximize procedures and maintain high continue reading this standards of high quality control.

Furthermore, real-time monitoring fosters a society of constant enhancement within the manufacturing setting. Workers are a lot more involved when they can see the influence of their work in real-time, causing increased accountability and a commitment to excellence. Overall, the implementation of real-time surveillance systems in optical Fibre production equates to premium item quality and increased customer fulfillment.

Effect On Production Performance

Carrying out optical Fibre Diameter analysers substantially boosts manufacturing performance by improving the production process. These tools facilitate continuous monitoring of Fibre Diameter, enabling makers to detect discrepancies in real-time. By recognizing disparities immediately, manufacturing lines can be adjusted promptly, minimizing downtime and decreasing the possibility of producing malfunctioning items.

Moreover, the combination of these analysers into the production workflow allows much better source allocation. With accurate Diameter measurements, drivers can enhance material use, making certain that resources are not thrown away on problematic fibers. This precision additionally adds to less remodel and scrap, ultimately reducing production prices.

The automation offered by optical Fibre Diameter analysers decreases dependence on manual assessments, which are prone and commonly lengthy to human error. Therefore, staff members can concentrate on more tactical tasks, enhancing general productivity.

Furthermore, the data created from these analysers can inform procedure enhancements and help with better decision-making. By analyzing fads address in Fibre Diameter variants, manufacturers can execute aggressive steps to boost production strategies and maintain regular top quality. In recap, optical Fibre Diameter analysers play a vital duty in boosting manufacturing effectiveness, causing higher high quality outcome and raised success.

Instance Researches and Success Stories

Across numerous markets, instance studies highlight the transformative impact of optical Fibre Diameter analysers on production procedures. One prominent instance is a leading telecoms business that dealt with difficulties with irregular Fibre sizes, leading to boosted rejection rates. By integrating an optical Fibre Diameter analyser, the firm accomplished real-time surveillance of Fibre measurements, causing a 30% reduction in defects and considerable cost savings.

Additionally, a research establishment focusing on sophisticated products utilized optical Fibre Diameter analysers to refine their experimental processes. The analyser's ability to supply detailed insights right into Fibre uniformity enabled the advancement of ingenious products with enhanced efficiency qualities.

These success tales highlight the important duty of optical Fibre Diameter analysers in improving high quality control, enhancing production efficiency, and driving technology across diverse sectors.

Verdict

In verdict, the Optical Fibre Diameter Analyser plays a crucial function in improving quality assurance within Fibre production. By giving specific, real-time dimensions and promoting prompt corrective actions, this technology substantially lowers variability and decreases waste. The execution of such advanced tools promotes a culture of constant renovation and functional effectiveness, inevitably ensuring conformity with sector criteria and maintaining competitiveness. As demonstrated through different situation researches, the analyser shows vital for attaining exceptional product top quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers permitted for rigorous high quality control, ensuring that the created fibers satisfied exacting sector criteria.In conclusion, the Optical Fibre Diameter Analyser plays an essential function in improving quality control within Fibre production.

Comments on “Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control”